PCB - Production Excellence System [PES]

- Know the pulse rate of your processes using our PES System.

- PES is a niche product which is exclusively customised for the Printed Circuit Board manufacturing industry.

- Process optimization can be successfully realised with 3S System, Smart monitoring, Smart Management & Smart Maintenance.

- System can be extended as a part Integrated Quality Management System

- Additionally, this system can also further customised to suit any manufacturing industry.

What is it?

- User friendly application which helps in monitoring the process behaviour.

- Tons of data can be quickly seen with a graphical representation.

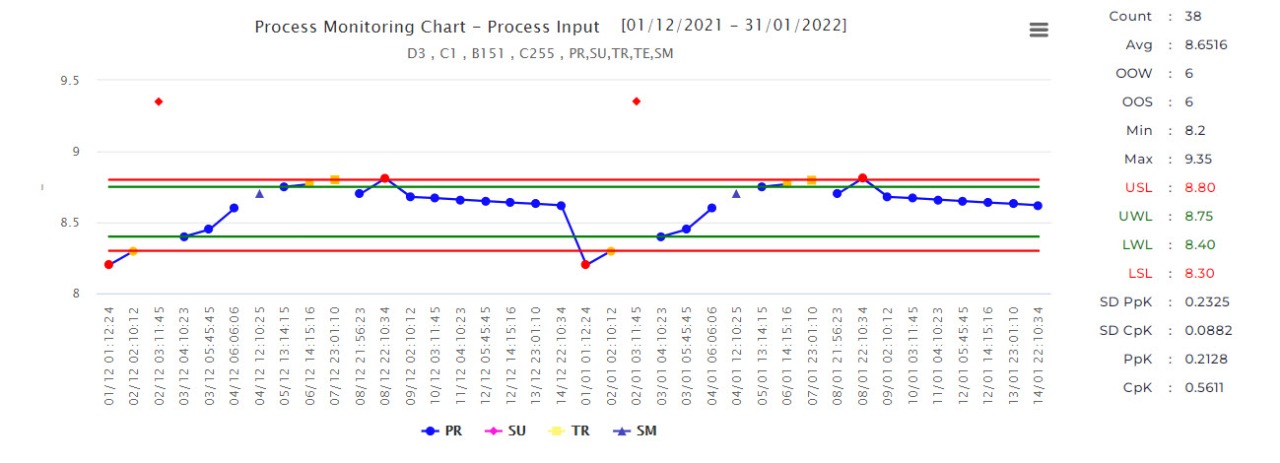

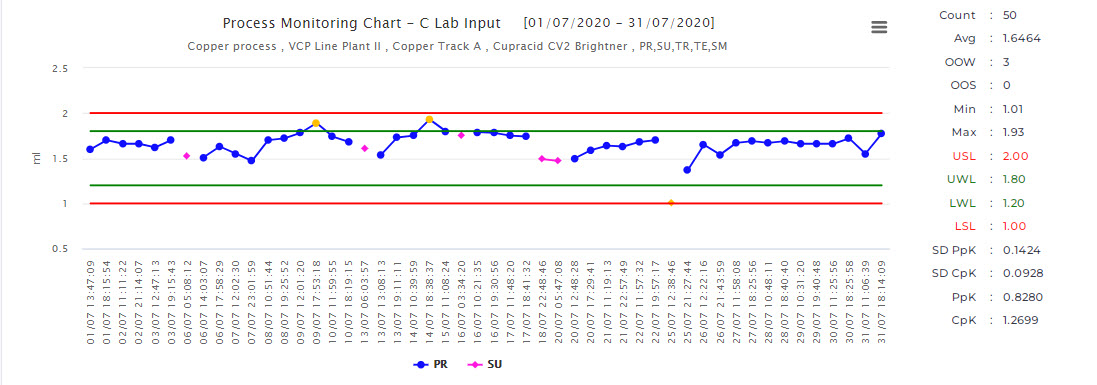

- Analyse data in many ways, i.e., Control, X-bar R, Trend charts, Pareto including calculation & analysis of Standard deviation, CpK/Ppk for each parameter & overall status of a process.

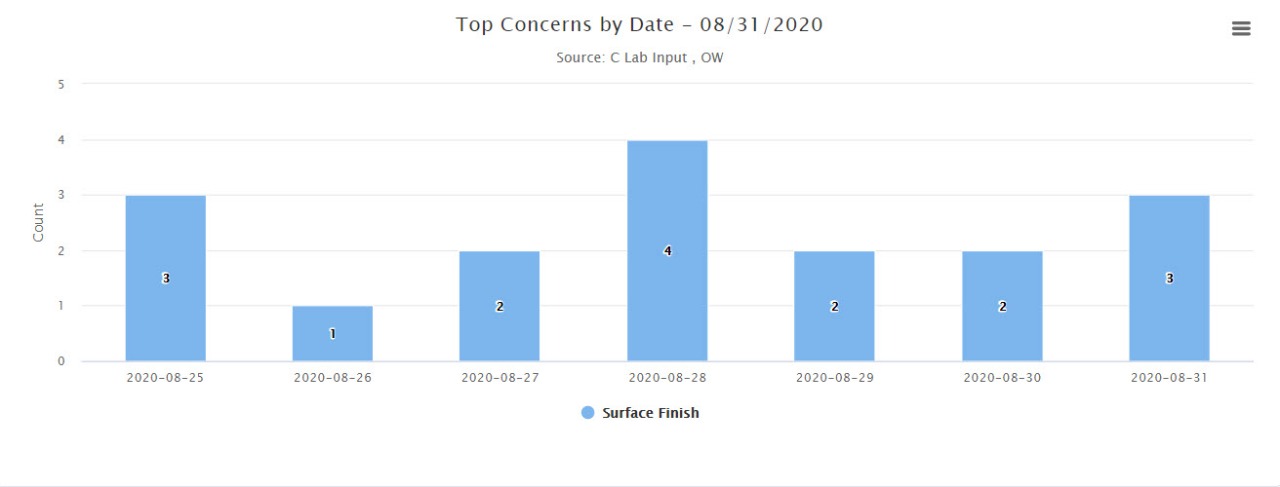

- Facilitates to record corrective actions for deviations and analyse the root causes. Reminds the process stake holders in a regular frequency if notifications are unattended.

- It also checks the actual analysis verses planned analysis according to control plan.

- Potentially, this application can be extended to all levels of ISA 95 functions in the manufacturing industry.

What is in it?

- Analysis of a process at any time, from anywhere by accessing PES App. through browsers.

- Top concerns of plant and top concerns of the processes are available by click of a button.

- PpK Trends and Pareto for all parameters calculated automatically & being monitored.

- Summary of pending corrective actions from any process at any time.

- Report of CAPA taken at the process for any parameter(s) for a selected period.

- 3 years rolling data availability in the App. & all the actions, trend, reports can be accessed, seen at any time.

- Option to upload missing data manually from external source (in case external [eg., SAP] source is down for several hours/days).

- Option to upload missing process data in case of App. being down for several hours/days.

- Many more…

Why is it?

- Not everyone can buy super expensive systems.

- Missing data driven culture in the manufacturing area.

- Industry 4.0 solution tool for managers to remotely monitor shop floor and to make decision towards operational excellence.

- Acts as a central nerves system for the processes.